Understanding the Roof Replacement Process and Costs

Orientation and Outline: Why Roof Replacement Matters

Roofs rarely fail all at once; they age the way a favorite jacket does—quietly, until one storm turns wear into worry. A replacement is more than a cosmetic upgrade. It safeguards your home’s structure, shields insulation, and protects everything under the ceiling from water, wind, and heat. Done thoughtfully, it can tame energy bills, reduce noise, and refresh curb appeal in a single project. The stakes are practical and financial: roofing issues are a leading cause of insurance claims, and moisture intrusion can escalate into costly repairs to sheathing, fascia, and interior finishes if left unattended. This article explains how shingles and other materials differ, what a precise installation involves, and how costs break down so that you can approach bids and timelines with clarity.

To set expectations, here is the roadmap we will follow:

– Materials at a glance: asphalt, metal, wood, slate, and composites, with lifespan, climate fit, and maintenance needs

– Step-by-step process: inspection, tear-off, underlayment, flashing, shingle layout, ventilation, and quality checks

– Cost structure: labor vs. materials, tear-off and disposal, permits, accessories, and realistic contingencies

– Decision drivers: roof geometry, local codes, weather windows, and warranty terms you can actually use

– Care and value: post-install maintenance, leak-preventing habits, and how a new roof influences resale

Before diving in, consider a few signals that a replacement, not a spot repair, may be the wiser choice: widespread granule loss leaving dark patches, curling or cracked tabs across multiple slopes, soft spots on decking, chronic attic condensation, or multiple leaks that reappear in different locations. If two or more of these show up, the system may be near the end of its service life. With that context, let’s move from the 10,000‑foot view to the shingles underfoot and build a plan that fits your home, climate, and budget without surprises.

Shingle Materials and Choices: Comparing Lifespan, Performance, and Style

Shingles are the visible layer of a larger weather system, and their material determines how the roof looks, lasts, and performs. The most common option is asphalt shingles with a fiberglass mat and mineral granules. They come in basic three-tab profiles and thicker architectural profiles. Typical lifespans range from roughly 15–25 years for many three-tab products and 25–40 years for architectural designs, depending on climate, sun exposure, and installation quality. Pros include accessible pricing, straightforward installation, and broad color choices; cons include susceptibility to heat cycling and potential granule loss over time.

Metal shingles or stamped panels mimic shakes, slate, or tile while delivering notable durability and fire resistance. Properly installed, they often last 40–70 years and shed snow efficiently on steeper pitches. They are lighter than many homeowners expect, but they do require careful flashing and trim detailing. Wood shingles and shakes offer a warm, natural look with good insulation value. In dry, well-ventilated assemblies, they can reach 20–30 years, but they demand periodic care in damp regions and are constrained by local fire codes. Natural slate is renowned for longevity—75–100+ years is common on well-built structures—and for its distinctive texture. Weight and cost are the main trade-offs; roofs may need structural evaluation before installation. Composite or polymer shingles aim to echo premium looks with more uniform weight and reduced breakage risk, generally landing in the 30–50 year range.

Climate should steer your choice. In hot, sunny zones, reflective surfaces and lighter colors can help reduce attic temperatures several degrees, easing HVAC loads. In coastal or high-wind areas, focus on wind ratings (look for products tested for uplift resistance) and corrosion-resistant fasteners. Regions with freeze-thaw cycles benefit from robust underlayment strategies and shingles with flexible sealants. Consider these practical checkpoints when comparing options:

– Lifespan vs. budget: balance initial cost with decades of service

– Weight and structure: confirm your framing can support heavier materials

– Fire, wind, and impact ratings: align the assembly with local hazards

– Availability and lead times: some premium profiles require advance ordering

– Maintenance realities: cleaning, moss control, and access for future repairs

Style matters too. Darker tones can anchor light façades, while mid-tone grays and weathered browns pair well with varied siding materials. Architectural profiles add depth that hides minor plane imperfections on older decks. By matching material performance with your home’s climate and design, you set the stage for a roof that looks right on day one and still performs years later.

From Tear-Off to Final Nail: The Roof Replacement Process Explained

A reliable installation follows an ordered rhythm, where each layer supports the next. It usually begins with protection: tarps draped to shield landscaping and siding, magnetic rollers staged for cleanup, and clear driveway space for the dumpster. Crews then perform a full tear-off, removing old shingles, nails, and underlayment to expose the deck. This is the truth-telling moment; soft or delaminated sheathing is marked and replaced so the new roof sits on a solid, flat surface. Next comes the drip edge along eaves and rakes to guide water into gutters and keep wind-driven rain from curling under the field.

In colder regions, an ice and water barrier is often installed along eaves and valleys to block meltwater intrusion. A synthetic or felt underlayment follows, rolled flat with neat overlaps and properly fastened to avoid tenting. Valleys are reinforced—either with metal valley flashing or woven shingles—depending on local practice and manufacturer requirements. Starter strips are installed at the eaves to anchor the first course and set the correct sealant line. Shingles are then laid according to a calculated offset pattern, with chalk lines keeping rows straight and nails driven in the designated nailing zone at the specified count per shingle. Cutting around penetrations is paired with step flashing at sidewalls and counterflashing where roofing meets masonry.

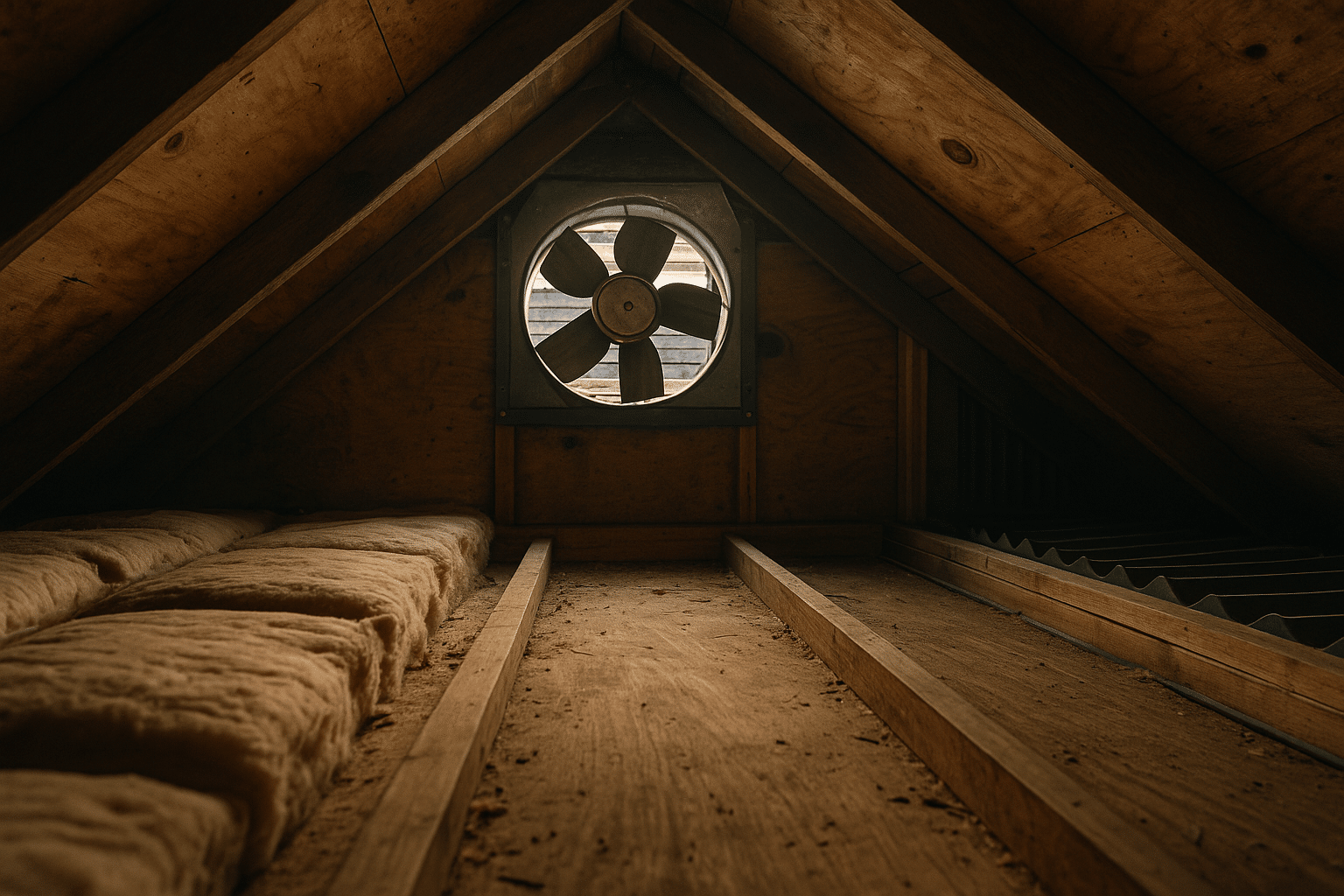

Ventilation is essential. Balanced intake at soffits and exhaust at ridge vents help purge warm, moist air, protecting shingles from heat aging and the deck from condensation. Ridge caps are installed last to finish the ventilation path and seal the peaks. Sealants are used sparingly for waterproofing, not as a substitute for proper flashing. A conscientious crew will then police the site for debris, run magnets multiple times, and walk the roof to check alignment, fastener exposure, and sealed joints.

Time frames vary with size and complexity. A simple, single-story gable roof can be completed in one to two working days with favorable weather. Complex roofs with multiple hips, dormers, and valleys can extend to four or more days. Weather matters: cold can slow sealant activation, while extreme heat can scuff granules, so crews may adjust schedules for quality. Key milestones to confirm with your contractor include:

– Pre-job meeting: scope, start time, staging, and protection plan

– Mid-job check: decking repairs, flashing approach, and ventilation strategy

– Final walkthrough: nailing, alignment, sealant points, cleanup, and warranty paperwork

When each step is performed in sequence and verified, the result is a system that manages water, air, and heat as designed—quietly doing its job for years.

What It Really Costs: Pricing Factors, Sample Budgets, and Smart Savings

Roofing costs are a mix of labor, materials, complexity, and logistics, and they vary meaningfully by region. As broad reference points for full replacement, installed prices often land around these ranges, though local conditions can shift them higher or lower: asphalt shingles about $4.50–$7.50 per square foot, wood shingles/shakes roughly $6.00–$10.00, composite/polymers around $7.00–$13.00, metal shingles or stamped panels near $8.00–$14.00, and natural slate at $15.00–$30.00 or more. Labor typically represents 55–70% of the total on asphalt projects, with steeper or more intricate roofs increasing time and safety measures.

Beyond the field shingles, several line items round out a realistic budget:

– Tear-off and disposal: about $0.50–$1.50 per square foot depending on layers and dump fees

– Decking repairs: $2.00–$5.00 per square foot for replaced sheathing where needed

– Flashing, vents, and accessories: $300–$1,200 based on roof size and penetrations

– Underlayment and ice/water barrier: variable by climate zone and code requirements

– Permits and inspections: $150–$500 depending on municipality

– Site protection and cleanup: sometimes bundled, but worth confirming in writing

To illustrate, consider a 2,000 square foot, one-story home with a moderately simple roof. Assume architectural asphalt shingles at $6.25 per square foot installed. Base install: about $12,500. Tear-off and disposal at $1.00 per square foot: $2,000. Permits: $300. Replace 100 square feet of damaged decking at $3.50 per square foot: $350. Flashing, vents, and ridge materials: $700. Estimated total: approximately $15,850. Add a contingency of 10% for surprises, especially on older homes, bringing the planning figure to about $17,400. Your numbers might differ, but this framework helps decode line items and compare bids apples-to-apples.

Saving without cutting corners is possible. Schedule during shoulder seasons when crews may have more flexibility. Keep roof geometry simple when planning additions; hips, valleys, and multiple dormers raise costs. Choose a widely stocked shingle profile and color to avoid special-order delays. Confirm that ventilation upgrades are included; a few hundred dollars spent on balanced intake and exhaust can extend shingle life and reduce moisture risk. Finally, compare workmanship warranties and confirm what triggers are required to keep them valid, such as annual inspections or simple maintenance steps.

Transparent pricing, a written scope that lists each component, and a contingency cushion create a budget you can live with—and a roof you can rely on.

Installation Quality, Care, and Long-Term Value: A Practical Conclusion

Even the most durable shingles cannot make up for sloppy details; long life comes from craftsmanship you can see and documentation you can keep. A quality checklist for installation day includes correct nail placement and count, snug step flashing at every sidewall, counterflashing where roofing meets brick or stone, straight courses guided by chalk lines, and a drip edge that runs continuously at eaves and rakes. Fasteners should be flush, not overdriven, and sealed if exposed. Ventilation should balance intake and exhaust to meet code and manufacturer guidance, typically measured in net free area per square foot of attic space. Ridge vents and baffles, paired with clear soffits, help prevent hot spots and condensation cycles that shorten service life.

Once the crew leaves, maintenance becomes your insurance policy against small issues turning big. Simple routines pay off:

– Inspect after major storms for lifted tabs, missing ridge caps, or displaced flashing

– Clean gutters and downspouts seasonally to prevent overflow into fascia and soffits

– Clear debris in roof valleys where leaves can trap moisture

– Trim branches that rub shingles and drop sap or seed pods

– Watch the attic for daylight at joints, damp insulation, or musty odors that signal ventilation problems

Documentation matters. Keep permits, invoices, material specs, and warranty cards together, and note the install date on a simple home maintenance calendar. If you plan to sell, a tidy packet showing a licensed installation, code compliance, and transferrable warranty can reassure buyers. In many markets, a midrange shingle replacement recoups a meaningful share of its cost at resale—often in the 55–65% range—while delivering comfort and peace of mind for as long as you own the home. Some assemblies also qualify for modest insurance discounts when they meet certain fire or impact ratings; ask your agent which documentation is needed to apply.

Viewed over decades, a roof is less a project than a partnership between materials, climate, and care. Choose a shingle that suits your region and style, hire a contractor who explains the process and invites questions, and commit to small, regular checkups. Do that, and your roof will do what the finest building systems do: quietly protect, season after season, without calling attention to itself—until the day you decide it’s time for a new look and another long run of worry-free shelter.