Essential Guide to Installing a Home Hot Tub

Introduction and Project Outline

Turning a corner of your home into a warm-water retreat is more than a weekend whim; it is a compact construction project with moving parts, timelines, and responsibilities. A filled hot tub commonly holds 300 to 500 gallons of water, which weighs roughly 2,500 to 4,200 pounds, plus the shell, equipment, and bathers. That total can approach the weight of a compact car, which is why planning foundations, access, plumbing, and power is essential. The reward is a space that supports relaxation, recovery after workouts, and friendly gatherings without leaving home.

Before lifting a finger, map the journey from idea to first soak. A simple outline keeps decisions rational and budgets steady:

– Goals and constraints: comfort, capacity, placement, and privacy

– Site conditions: soil, drainage, sun and wind exposure, and nearby trees

– Delivery path: gate width, slopes, corners, and overhead lines

– Foundation: slab, pavers on a compacted base, or a reinforced deck

– Utilities: electrical supply, bonding, and a safe drainage plan

– Maintenance plan: water chemistry, filter care, and seasonal routines

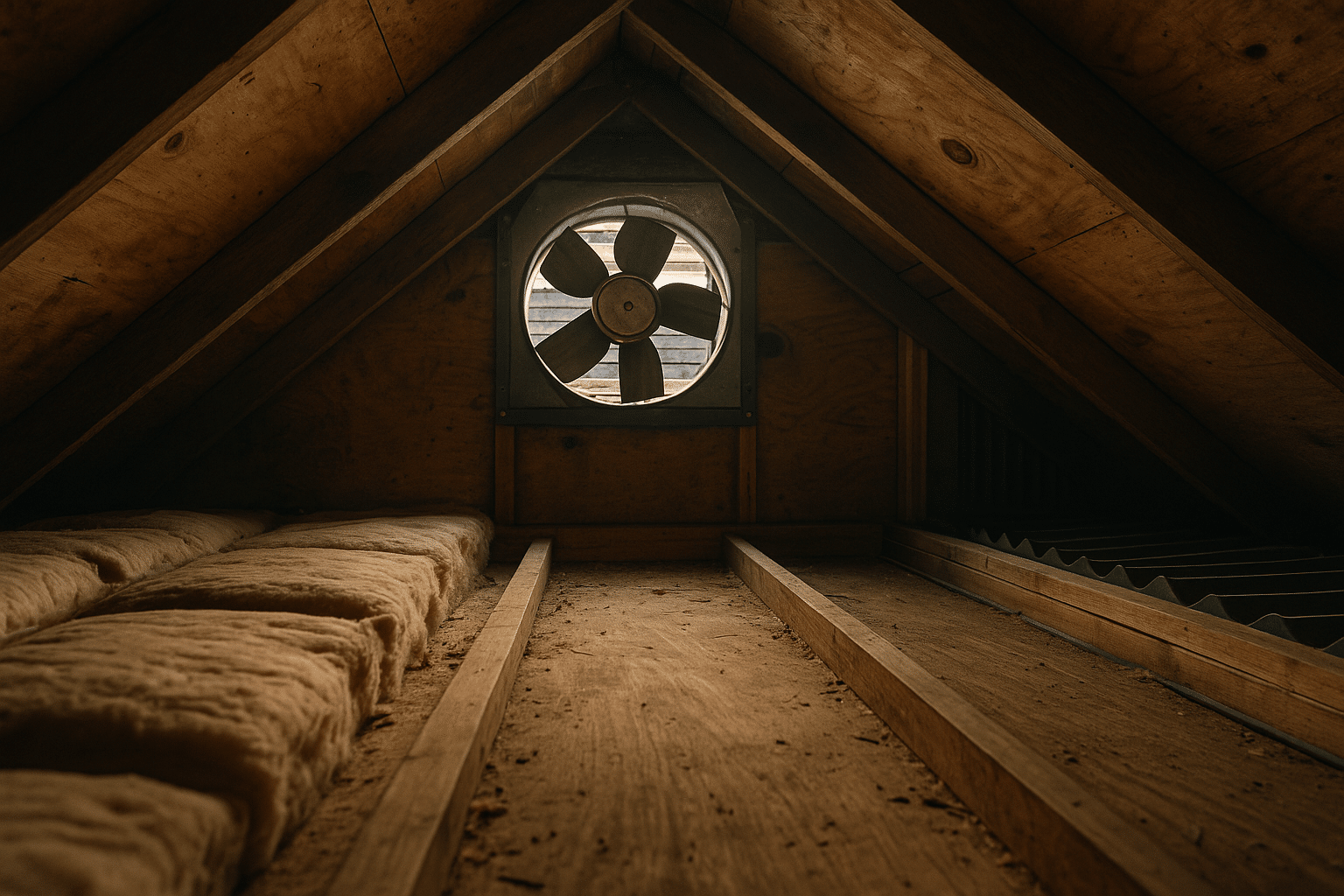

Timeline expectations help too. Lead times for electricians or concrete work can run one to four weeks in busy seasons, with inspections adding a few days. Some municipalities classify portable spas similarly to pools, triggering barrier or cover requirements and placing limits on set-back distances. If you plan an indoor location, add ventilation and moisture control to the checklist; warm, humid air can condense inside walls, so a vapor barrier and a controlled exhaust route are as important as the tub itself.

Here is the road map we will follow: site preparation and installation steps that fold in safe electrical practices; plumbing fundamentals that show how water moves through pumps, heaters, and jets; daily-to-seasonal maintenance that keeps the water inviting; and a concluding checklist that ties cost, safety, and workflow together. Think of it as a small build with a big payoff: deliberate planning now prevents cracked slabs, tripped breakers, cloudy water, and lost weekends later.

Site Preparation and Installation Steps

The smoothest installations start with access. Measure the narrowest gate, side yard, or hallway the tub must pass through; many shells need 36 to 42 inches of clear width and a fair turning radius. If the path is too tight, a temporary fence panel or a short crane lift may be more economical than forcing a risky squeeze. Also scan above: low eaves and overhead wires can complicate a delivery and should be discussed with your installer or utility locator.

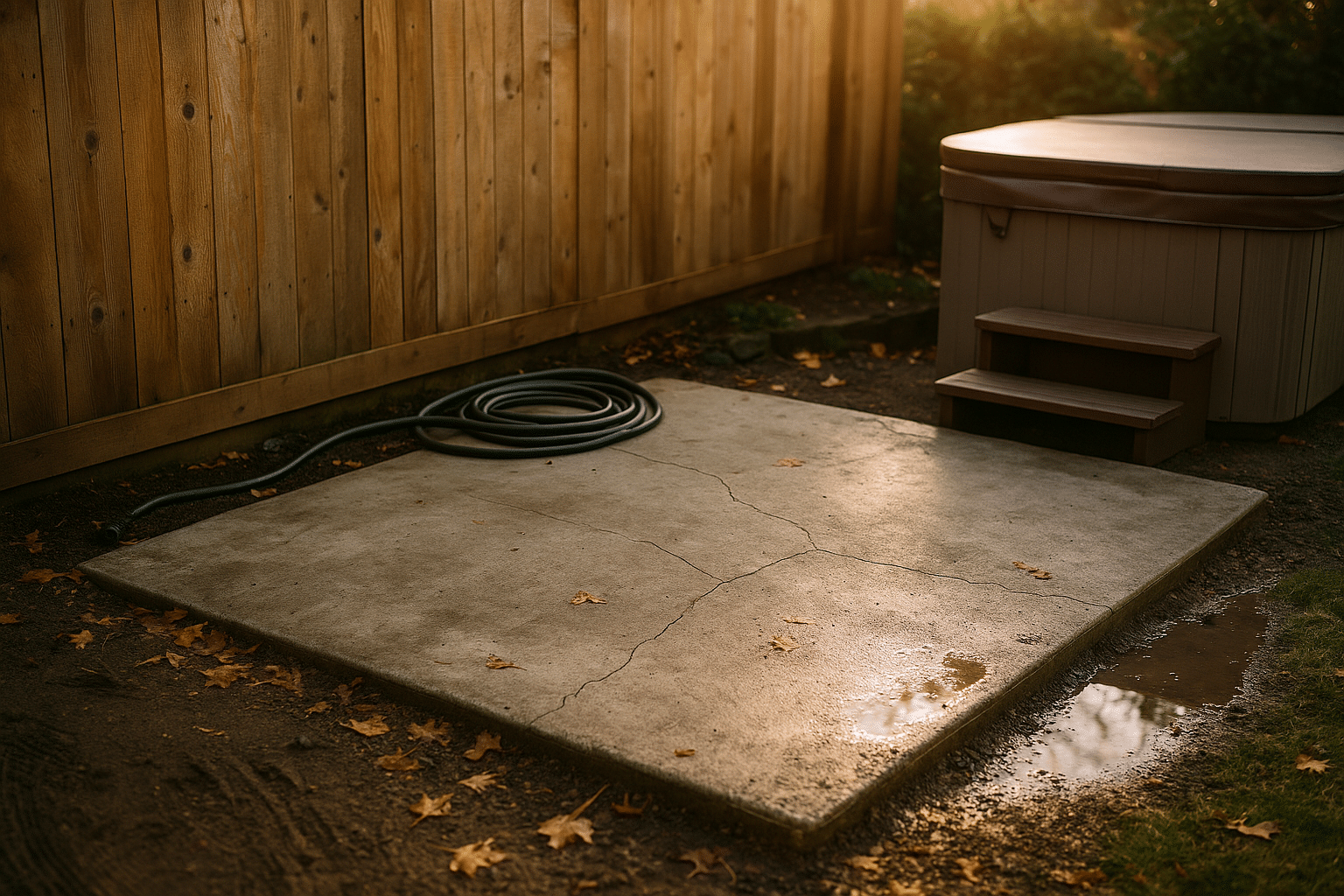

Next, choose a foundation that stays flat, dry, and strong. A poured concrete slab remains a reliable favorite: 4 inches thick with compacted base beneath, a slight slope of about 1/8 inch per foot for drainage, and control joints to manage cracking. On stable soil, pavers over 6 to 8 inches of compacted gravel can work, provided the aggregate is well graded and the surface is laser-level before the tub arrives. Deck installations demand careful math; many tubs with water and people can load 100 to 125 pounds per square foot. Joist sizing, beam spans, and footings should be verified by a qualified pro if you plan an elevated platform.

Electrical planning folds into installation day. Most full-featured units run on a dedicated 240-volt, GFCI-protected circuit sized between 30 and 60 amps, with a weather-resistant disconnect typically placed within line of sight and several feet from the water’s edge, per common code practice. Some smaller, “plug-in” models use a 120-volt, 15- to 20-amp GFCI circuit but heat more slowly and may limit pump operation while heating. Conduit route, wire gauge, and bonding connections to nearby metal objects deserve professional attention for safety and code compliance.

With the base and power ready, set the tub, align it, and verify level in multiple directions; small adjustments now prevent uneven waterlines and stress on the shell later. Connect the equipment according to the manufacturer’s diagrams, fill through the filter well to help prime the pumps, and check for drips at unions as the system pressurizes. For indoor or enclosed spaces, include ventilation: a controlled exhaust path and a vapor barrier protect framing and insulation from constant humidity.

To keep the day organized, run a short step list:

– Confirm delivery path and clear obstacles

– Verify slab or deck is level, well-drained, and cured

– Install electrical disconnect and GFCI on a dedicated circuit

– Set and level the tub, then connect equipment bay components

– Fill through the filter well, power up, and check for leaks and proper pump prime

– Add start-up chemicals after heating begins, following label guidance

Budget-wise, a small slab might range from a few hundred to low four figures depending on sitework, while electrical work varies with distance from the main panel and local rates. Planning for these costs up front avoids surprises that can stall the project just when excitement peaks.

Plumbing Fundamentals and Water Management

Hot tub plumbing looks like a maze at first glance, but it follows a logical loop: draw water from the vessel, move it through filtration and heating, distribute it to jets, and return it to the shell. At the heart are two pump styles—one for strong jet action and one for quiet circulation in many models—and a heater that raises water temperature slowly but steadily. The filter, often a pleated cartridge, traps fine particles before water is sent back to the bathers.

Pipes and manifolds split flow from the pumps to multiple jets. Many systems use 2-inch lines for the main runs to reduce friction loss, then step down to 1.5-inch branches feeding seats and footwells. Every elbow adds resistance, so gentle sweeps reduce head loss better than sharp 90-degree turns. Strategically placed unions allow easy removal of pumps and heaters for service, and true-union ball valves make shutoffs tidy during repairs. Check valves prevent backflow that could drain lines unintentionally when pumps stop.

Air induction adds sparkle to the jets. Small air lines meet water lines near the jet bodies, mixing bubbles into the stream; adjustable air controls let you fine-tune the feel. Suction fittings must remain unobstructed to prevent entrapment. Keep hair, clothing ties, and accessories clear of drains during use, and ensure protective covers remain intact and compliant with current safety standards.

Assembly details matter. Primer and solvent cement for PVC require clean, dry pipe ends and fittings; test-fit, mark alignment, then apply primer and glue to both surfaces before a quarter-turn push. Hold for several seconds to prevent pushback and allow adequate cure time per product instructions, often 15 minutes for handling and longer before pressurizing. A slow fill helps identify any weeping joints so you can snug a union or re-seat a gasket before the system reaches operating pressure.

Water in must be clean; a simple pre-filter on a garden hose reduces metals and sediment that can discolor surfaces. Water out must be legal and kind to landscaping. Many areas require dechlorination before discharge and prohibit sending water to storm drains. Let sanitizer dissipate for a day or two with the cover open, or use a neutralizer as directed, then drain to a permeable area that can absorb the volume without erosion.

In cold regions, freeze protection is about circulation and insulation. Keep the circulation pump active, verify cabinet insulation is intact, and close cabinet panels after service. If you must shut down for winter, purge water from lines using a wet-dry vac and follow local guidance on non-toxic antifreeze intended for recreational water systems. Thoughtful plumbing choices and a clean fill set the tone for clear, quiet operation long after installation day.

Maintenance, Water Care, and Seasonal Routines

The secret to a consistently inviting hot tub is a light, steady maintenance rhythm rather than sporadic marathons. Start with water balance. Aim for pH around 7.2 to 7.8, total alkalinity near 80 to 120 parts per million, and calcium hardness in the 150 to 250 range for most acrylic shells. Balanced water protects heaters and pumps from scale, reduces eye and skin irritation, and helps sanitizers work efficiently.

For sanitizing, common options include chlorine, bromine, or non-halogen systems. Chlorine is familiar and effective at 1 to 3 ppm in spas when paired with regular oxidation. Bromine holds up well at higher temperatures and typically operates around 3 to 5 ppm with a floater or feeder. Non-chlorine oxidizers can supplement either approach to break down oils and lotions introduced by bathers. Whatever you choose, test water a few times per week with fresh strips or a drop kit and adjust gently rather than making large swings.

Build a schedule you can live with:

– After each use: run a 15–20 minute clean-up cycle to filter bather load

– Weekly: test and adjust pH and alkalinity; sanitize; shock with an oxidizer

– Biweekly: remove and hose-rinse filters; wipe waterline to prevent film

– Monthly: deep soak filters in a cleaner, then rinse thoroughly

– Every 3–4 months: drain, purge lines per product instructions, refill with a pre-filter, and rebalance

Filter care is the unsung hero. A clogged filter forces pumps to work harder, reduces jet strength, and can trigger flow or heater faults. Keep a spare set to swap in while the dirty one soaks; alternating extends lifespan and keeps downtime short. Covers deserve care too: rinse underside condensate, clean and condition the exterior per material type, and check seams for wear so heat does not leak into the night air.

Energy management is a quiet money saver. In mild climates with a well-insulated cabinet and cover, daily use might add a modest number of kilowatt-hours; in harsher winters, expect more. Practical tactics include reducing wind exposure with fencing or shrubs, using a thermal blanket under the main cover, and maintaining a steady setpoint rather than letting water cool completely between soaks. For indoor tubs, keep humidity in check to protect finishes and improve comfort.

Troubleshooting basics cover most hiccups. Cloudy water often traces to low sanitizer or insufficient filtration—raise sanitizer to target and extend filtration cycles. Foaming points to soap residues; ask guests to skip lotions and use a defoamer sparingly while planning a water change. Scale on heaters or shells signals high pH or hardness; use a scale inhibitor and restore balance. If a heater does not engage, confirm water level, clean filters, and check that flow switches are satisfied before calling a technician. With a steady routine, issues become rare and quick to resolve.

Conclusion and Final Checklist

Bringing a hot tub home blends construction savvy with everyday practicality. When you plan the foundation, route utilities cleanly, respect local safety rules, and commit to simple water care, the result feels effortless: warm, clear water on demand and equipment that hums along quietly. Costs vary with site conditions, but thoughtful budgeting paints a clearer picture. A small slab and site prep may land in the hundreds to low thousands depending on excavation and access. Electrical work typically ranges based on panel capacity, wire run, and local labor, and operating costs scale with climate, insulation quality, and how often you soak. Add consumables—sanitizer, test supplies, and filter media—modestly over the year, and you have a realistic view of ownership without surprises.

Use this checklist to close the loop before the first soak:

– Verify permits, barriers, and set-backs where required

– Confirm delivery path clearance, including corners and overhead lines

– Choose a base: slab, pavers over compacted gravel, or engineered deck

– Install GFCI-protected power on a dedicated circuit with a visible disconnect

– Level the tub, fill through the filter well, and confirm pump prime and leak-free unions

– Balance water, set filtration cycles, and document a weekly maintenance plan

– Inspect the cover fit, locking hardware, and any safety signage or barriers

– Establish a winter plan: continuous operation or proper shutdown steps

If you are a hands-on homeowner, these steps keep control in your hands while knowing when to call in licensed pros for electrical work or structural verification. If you prefer turnkey service, the same framework helps you evaluate quotes and timelines with confidence. Either way, an organized approach typically trims delays, reduces rework, and extends the life of the equipment. Think of your tub as a small ecosystem: stable foundation below, reliable energy and water pathways around it, and clear care routines above. Get those in harmony and the rest is simple—lift the cover, watch the steam curl into the evening air, and enjoy the quiet reward of a project well planned.