Understanding the Benefits of Professional Roof Coating Services

Outline:

– The role of roof coatings in waterproofing, insulation, and energy performance

– Waterproofing fundamentals: substrates, details, and durability

– Thermal comfort and insulation: what coatings do and do not do

– Energy efficiency and cost: reflectivity, emissivity, and payback

– Materials, climate fit, professional practice, and a practical conclusion

From Leaks to Lower Bills: How Coatings Connect Waterproofing, Insulation, and Energy Efficiency

Think of a roof coating as a calm, continuous tide washing over old seams and screws, turning a patchwork surface into a single, protective skin. This film—often elastomeric—bridges hairline cracks, seals fasteners, reflects sunlight, and sheds water. In practice, that means fewer opportunities for leaks, gentler rooftop temperatures, and potential energy savings, especially in warm, sunny climates. While coatings are not a substitute for structural repairs or proper insulation, they add a strategic layer of defense that can extend roof life and reduce lifecycle costs. The draw for building owners and homeowners is clear: coatings are applied with limited disruption, usually over existing membranes or metal panels, and can postpone more invasive tear-offs.

Three pillars justify coating projects. First, waterproofing: modern formulations can stretch to accommodate thermal movement (common elongation values exceed 200%) and form a monolithic barrier around penetrations. Second, thermal moderation: by boosting solar reflectance (often 0.65–0.85) and thermal emittance (commonly >0.85), coated roofs heat up more slowly and cool down more quickly under the sun. Third, energy efficiency: lower rooftop temperatures can translate into reduced cooling loads, a benefit that compounds during long, hot seasons. These gains are strongest where cooling dominates the energy profile; in cold regions, reflectivity can introduce a mild wintertime trade-off, which energy modeling can quantify before you commit.

To set expectations, consider how coatings fit into a roof’s whole system. They excel at sealing micro-defects and reflecting heat but will not correct failed deck slopes, saturated insulation, or rotted decking. A credible plan includes surface preparation and repairs before coating, ensuring the new layer adheres and performs. Useful checkpoints include:

– Identify wet insulation with infrared or core cuts before encapsulating problems.

– Repair blisters, splits, and open seams; replace incompatible patches.

– Prime where required and respect manufacturer-specified dry film thickness (often 20–40 mils for base/finish).

When these fundamentals are in place, coatings can help transform a vulnerable roof into a durable, cooler, and easier-to-maintain surface.

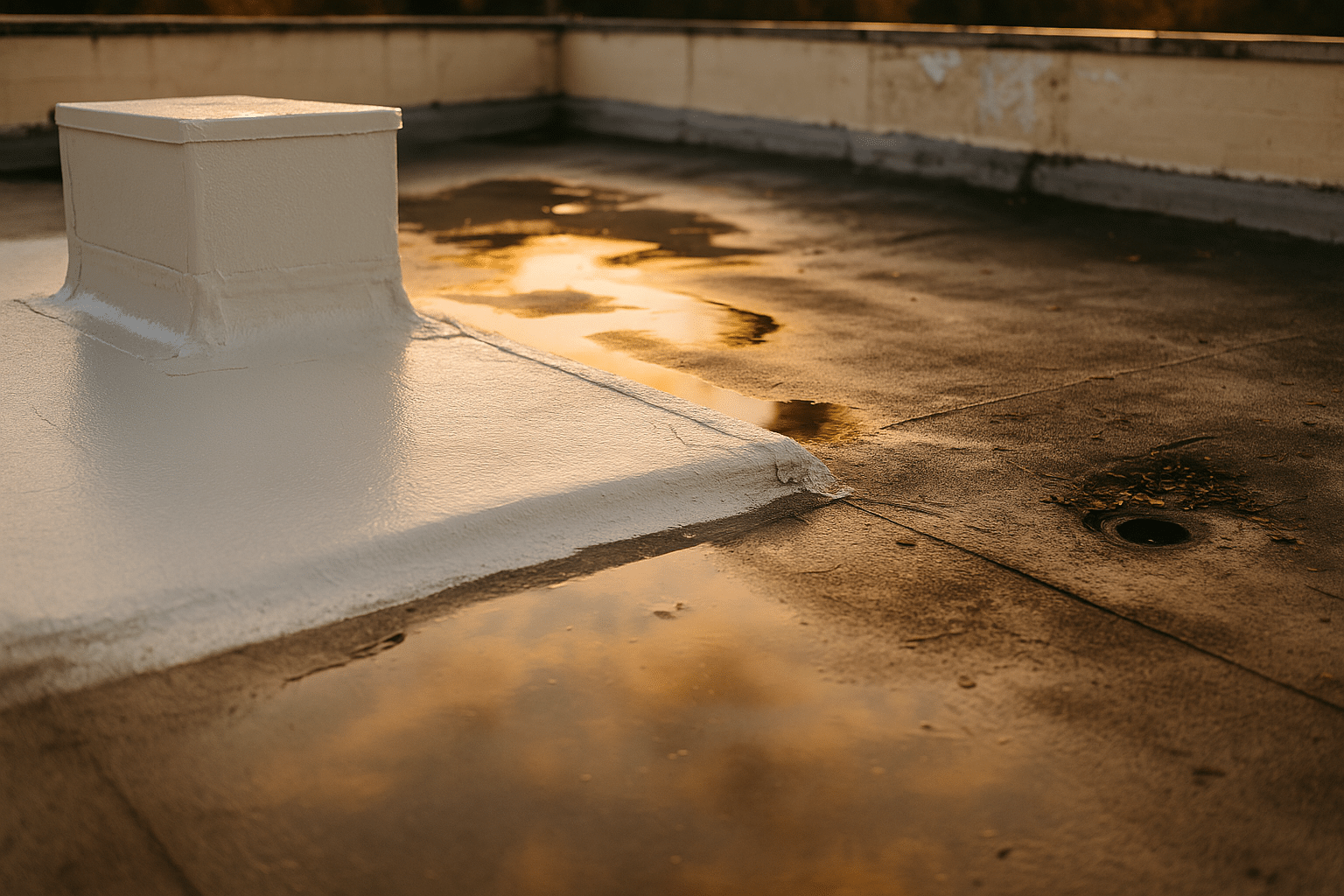

Waterproofing Fundamentals: Building a Monolithic Shield Above Your Head

Water will always search for the path of least resistance, so waterproofing succeeds or fails at the details. A professional coating system treats the field of the roof and the “weak points” alike: fasteners, seams, terminations, curbs, parapets, and drains. The goal is a seamless, continuous membrane with adequate thickness and strong adhesion. Typical systems combine reinforced mastics at joints with a field-applied coating, producing a layered result that tolerates thermal movement and daily weather stress. On metal roofs, for example, the process often includes tightening or replacing fasteners, treating panel laps with a mesh-reinforced flashing grade, and then applying the field coat to tie it all together.

Substrate compatibility is essential. Coatings must match the chemistry and condition of what they are covering—single-ply, modified bitumen, BUR, concrete, or metal. Acrylics tend to be favored for UV resistance and color retention; silicones are known for their tolerance of intermittent ponding; polyurethanes offer abrasion and chemical resistance; asphaltic or emulsion layers can build thickness economically under a reflective topcoat. Each chemistry has trade-offs. For instance:

– Acrylics generally prefer positive drainage and perform admirably in sunny, dry climates.

– Silicones can handle areas that experience standing water but require clean, well-prepped surfaces.

– Polyurethanes excel where foot traffic or mechanical abuse is expected.

– Hybrid systems can balance performance and cost when specified thoughtfully.

Durability hinges on film build and adhesion. Dry film thickness for the field coat commonly lands between 20 and 40 mils, with flashing areas thicker. Pull tests and adhesion tests help verify bond strength to the existing membrane or metal substrate. Proper preparation is non-negotiable: pressure washing, rust treatment on steel, addressing loose aggregate on BUR, and priming where required. Moisture matters, too; trapped water can cause blistering or adhesion loss. That is why professionals frequently perform:

– Moisture surveys to flag saturated insulation for removal.

– Test patches to confirm adhesion and compatibility.

– Detail mockups to refine application around curbs and drains.

When executed well, the result is a monolithic surface that sheds water, resists UV degradation, and slows weathering of the underlying roof. In many maintenance logs, leaks concentrate at penetrations and terminations; reinforcing those nodes during a coating project often yields outsized gains in reliability. The payoff is not only fewer emergency calls during storms but also a calmer maintenance plan, guided by periodic inspections rather than urgent bucket brigades.

Insulation and Thermal Comfort: Setting Expectations and Boosting Performance

Coatings influence heat flow primarily through reflectivity and emissivity, not through high R-value. Insulation resists conductive heat transfer; coatings manage radiant heat by reflecting solar energy and emitting absorbed heat back to the sky. That distinction matters. If a roof lacks insulation or contains wet, degraded boards, adding a reflective coating will not deliver the same comfort as upgrading insulation. Still, a reflective topcoat can lower surface temperatures by 20–50°F (about 11–28°C) under intense sun, reducing heat flux into the assembly and helping HVAC equipment work less.

On a typical low-slope assembly with R-20 to R-30 insulation, improving solar reflectance from ~0.25 to ~0.75 can reduce summertime roof surface temperatures dramatically. Indoors, occupants may notice steadier temperatures near the top floor and fewer “hot spots” late in the afternoon. In some climates, building operators observe:

– Shorter compressor run times and fewer peak-demand spikes.

– More stable duct supply temperatures, especially in rooftop packaged units.

– Reduced thermal expansion/contraction stress at seams and penetrations.

What about so-called “insulating” coatings? Some products include ceramic or hollow microspheres that may slightly change the thermal behavior at the surface. While lab tests can show differences in emissivity or thermal diffusivity, these films do not replace traditional insulation in terms of R-value. A sound approach is layering strategies: keep or upgrade the insulation in the assembly where feasible, and cap it with a reflective, durable coating tailored to climate and drainage conditions. The combination balances conductive resistance (insulation) and radiant control (coating), preserving the assembly while moderating rooftop heat.

Ventilation and moisture management also play supporting roles in perceived comfort. Preventing vapor from becoming trapped under the membrane, sealing air leaks around penetrations, and ensuring drains stay clear all contribute to stable indoor conditions. In short, think of coatings as the outer canvas that reflects and protects, while insulation is the quilt beneath it that truly keeps the heat flow in check. Aligning both elements—plus vigilant moisture control—delivers a noticeable improvement that feels less like a single upgrade and more like a tuned system.

Energy Efficiency in Numbers: Reflectivity, Emissivity, Payback, and Carbon

Energy outcomes depend on climate, building use, roof area, and HVAC efficiency. Even so, reflective coatings have a measurable track record in cooling-dominant regions. By elevating solar reflectance from around 0.2–0.3 to 0.7–0.85 and thermal emittance above 0.85, the solar heat gain on the roof drops substantially. For a simplified example, consider a 50,000 ft² low-slope commercial roof. If cooling demand is significant for eight months of the year and electricity costs $0.12/kWh, published case analyses and energy models often estimate reductions in cooling energy on the order of 5–20%, with higher values at the upper end in hot, sunny zones.

Here is a conservative illustrative scenario. Suppose baseline annual cooling energy is 800,000 kWh. A 10% reduction from reflectivity and emissivity improvements would save 80,000 kWh per year, or about $9,600 at the stated rate. If the installed coating system costs $2.50–$4.50 per ft² (including prep, detail work, and two coats), the project cost might be $125,000–$225,000. Simple payback in this scenario lands roughly between 13 and 23 years, but incentives can compress that range. In many markets, utility rebates or tax mechanisms offset a portion of cost, and energy savings combine with avoided leak repairs and deferred replacement to produce a more favorable lifecycle profile than simple payback suggests.

Thermal benefits arrive alongside operational ones. Lower roof temperatures reduce thermal stress cycles, which can slow aging of seams and accessories, indirectly preserving the assembly and potentially improving reliability. Facilities that face peak-demand charges may see added value: shaving late afternoon rooftop temperatures can temper demand spikes. It is common to see:

– 15–35°F reductions in rooftop HVAC intake air temperatures under sun.

– Fewer nuisance shutdowns linked to overheated equipment on roof decks.

– Improved occupant comfort near upper floors, trimming supplemental cooling needs.

Carbon impact follows the electricity meter. Using a generic grid factor of 0.7 lb CO₂/kWh (actual values vary widely by region), the 80,000 kWh annual savings above equate to roughly 56,000 lb of CO₂ avoided each year. Over a 10-year service interval before recoat, that is more than a quarter-million pounds avoided, assuming performance is maintained and the building’s use patterns hold. The key is to confirm conditions: roofs with heavy shading, brief cooling seasons, or significant winter heating loads may yield smaller net benefits, so a quick energy model tied to your local weather file is a wise early step.

Materials, Climate Fit, Professional Practice, and a Practical Conclusion

Coating chemistry should match the job. Acrylics, silicones, polyurethanes, and asphalt-emulsion systems each have strengths. Acrylics offer strong UV durability and color retention, excelling on roofs with positive drainage; silicones tolerate intermittent ponding and intense UV; polyurethanes handle abrasion and mechanical wear; asphaltic bases can build film economically under a reflective finish. Climate nudges the decision. Hot-arid regions reward high reflectivity and UV stability; humid climates add the need for mold/mildew resistance and robust adhesion; coastal zones demand attention to salt exposure and metal corrosion; cold regions call for flexibility at low temperatures and planning for snowmelt pathways. Practical fit also depends on roof type: metal panels, aged single-ply, modified bitumen, or BUR each require tailored prep and primers.

Professional application is about planning, not just product. The process typically includes inspection, moisture testing, surface preparation, detail reinforcement, field coating with verified wet-film and dry-film thickness, and post-cure inspection. A dependable contractor will document:

– Substrate condition and repairs, including photos of wet insulation removals.

– Adhesion tests and any primers used.

– Measured film thickness by area, flashings, and field.

– Weather conditions during application and cure windows.

These records become the backbone of maintenance and any guarantees. After completion, maintenance is straightforward: semiannual inspections, post-storm checks, clearing drains, touching up damaged areas, and recoat planning before the film erodes to the point of exposing the substrate.

Conclusion for Homeowners and Facility Managers

If you are weighing roof upgrades, a professionally specified and applied coating can offer a measured, low-disruption path to a tighter, cooler, longer-lived roof. It reinforces waterproofing at the weakest points, tamps down rooftop heat in sunny seasons, and can deliver meaningful energy savings where cooling dominates. Success hinges on honest diagnostics—fix what is wet or broken first—followed by a chemistry and thickness tailored to your climate and roof type. With that sequence, coatings become a practical tool in your building’s playbook: not a cure-all, but a smart layer that protects your investment and makes day-to-day operation a little easier.